Skills utilized: Rapid Prototyping, 3D Printing, Design for Manufacturability (DFM), R&D, PCB Design

I developed a modular LED matrix for special event lighting. The matrix is integrated into an end-supported fabric by custom 3D printed snap fits. The laser cut metal plates clamp down at each end to create rigidity along the length of the fabric.

The LEDs are integrated with a 3D printed light diffuser. The diffuser along with the top coupler, snap into the fabric creating a tight clamping force.

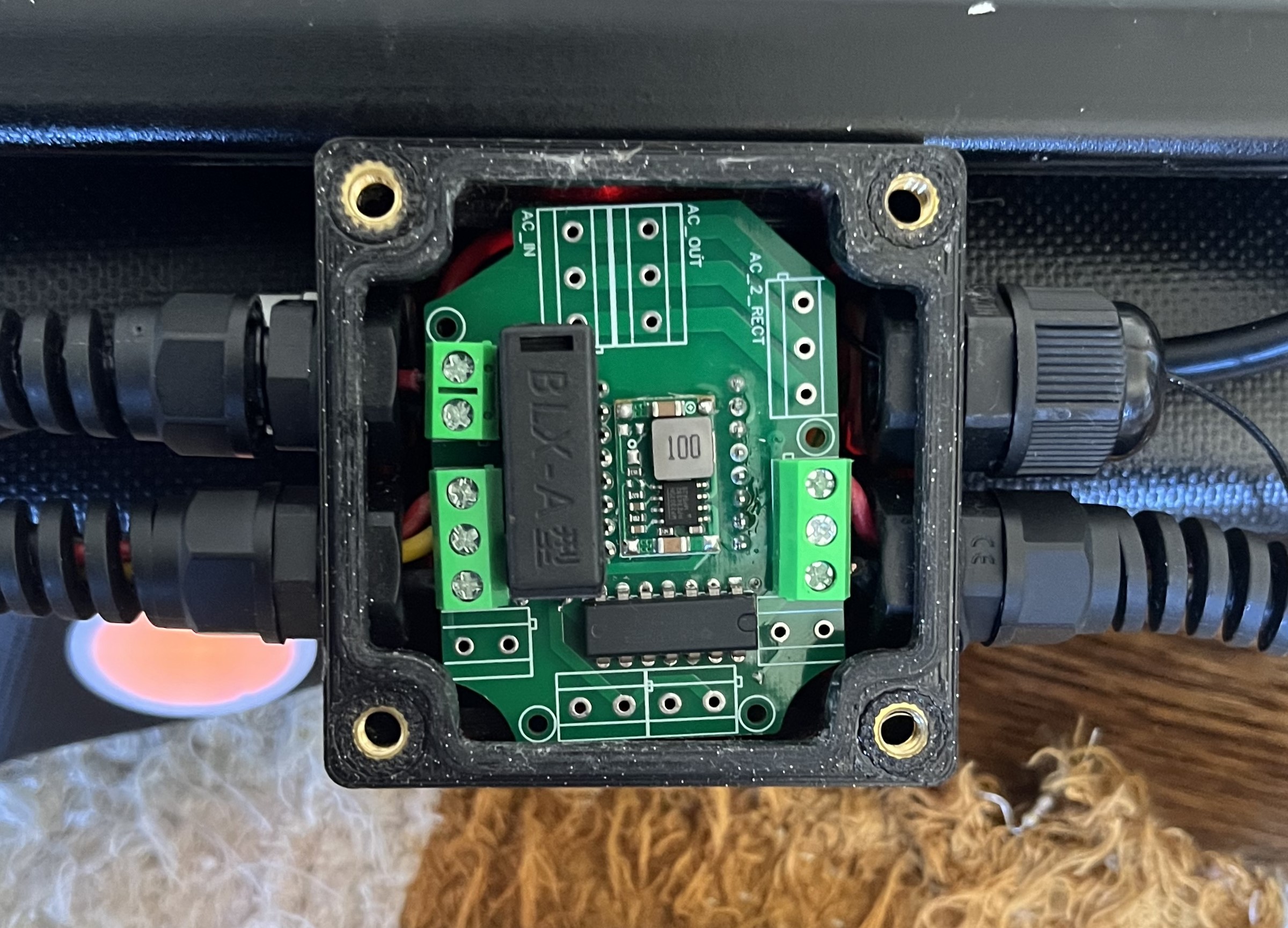

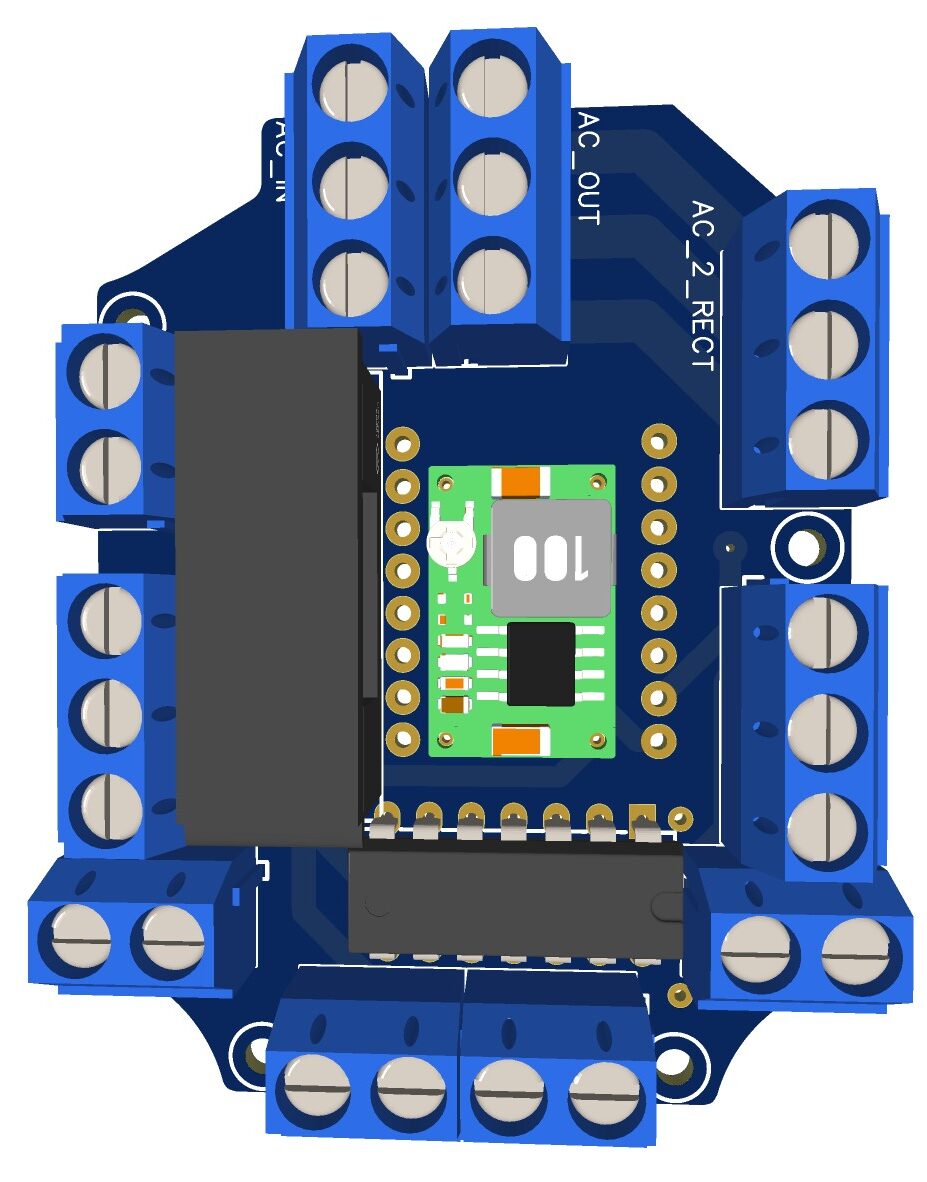

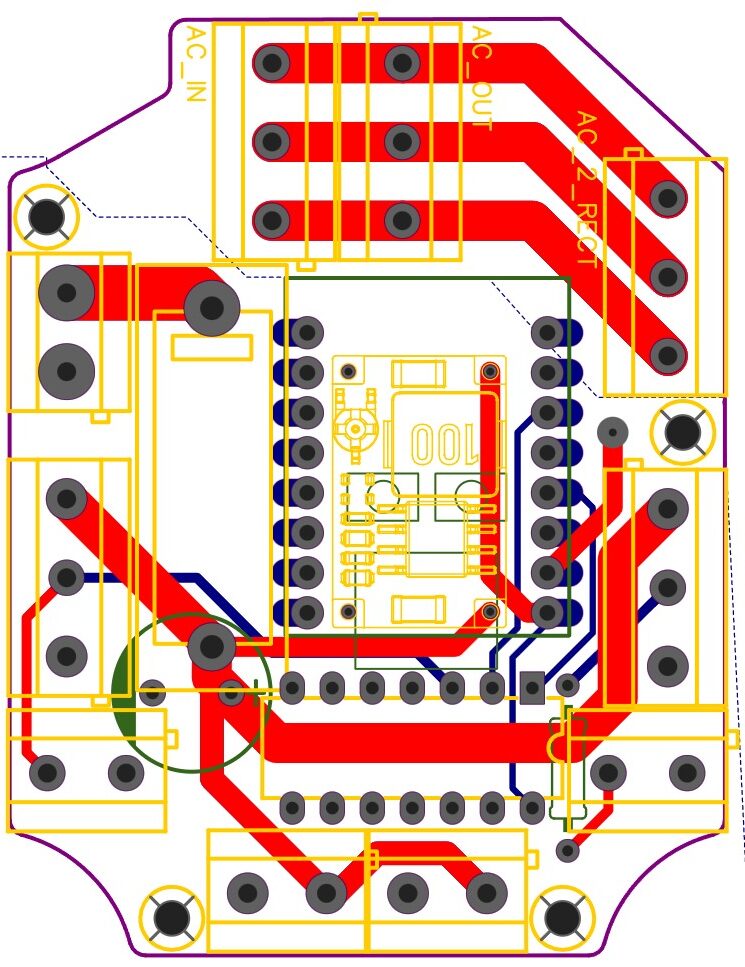

I designed a custom PCB to minimize soldering labor and increase system robustness. The enclosure acts as a power distribution hub for both AC and DC circuits.

The DC side is distributed to various LEDs by injecting power to reduce voltage drop from in the wires. The 12V input is stepped down to 5V to power the ESP32 (bottom of board). An additional chip shifts the LED signal from 3.3V to 5V as per required by the LEDs.

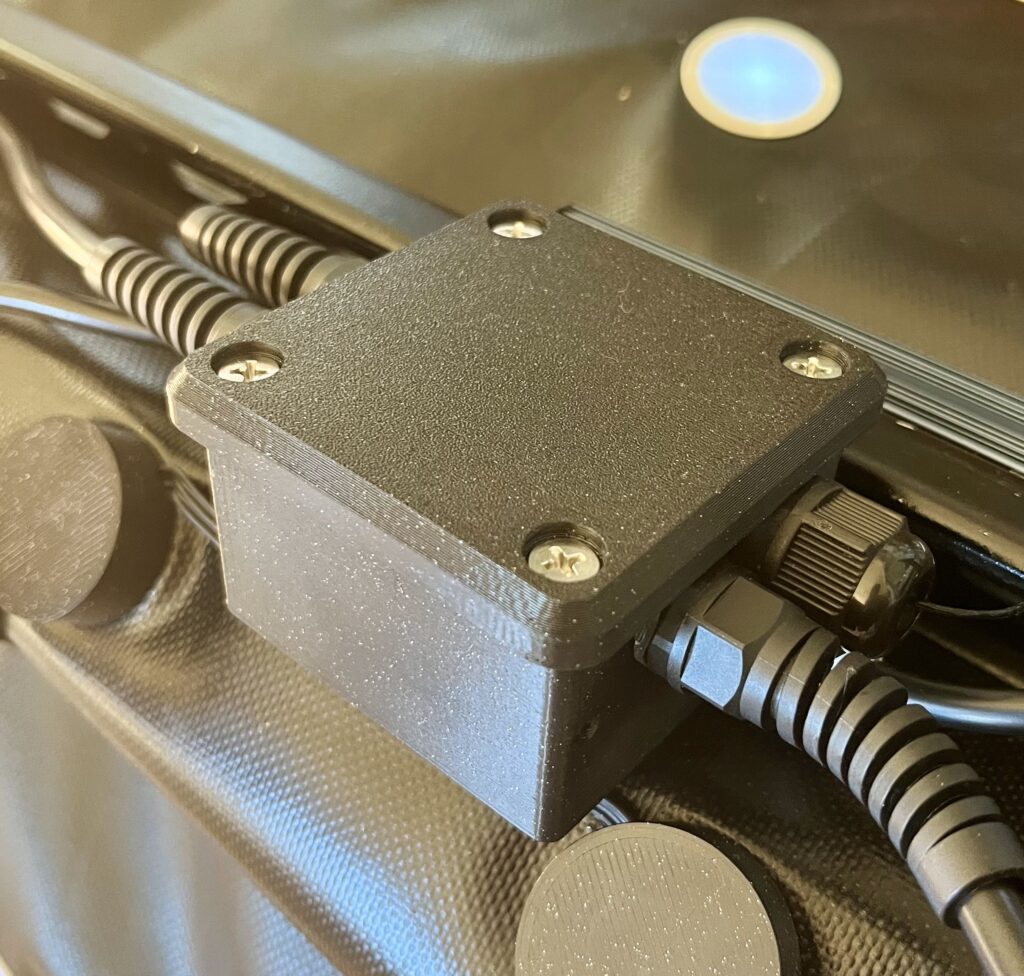

I also designed a custom 3D printed waterproof enclosure to house the electronics. A rubber gasket is squished between the yellow and grey pieces above to create a waterproof seal.