Skills utilized: Solidworks Motion Study, Mechanical Linkage Design, Fabrication

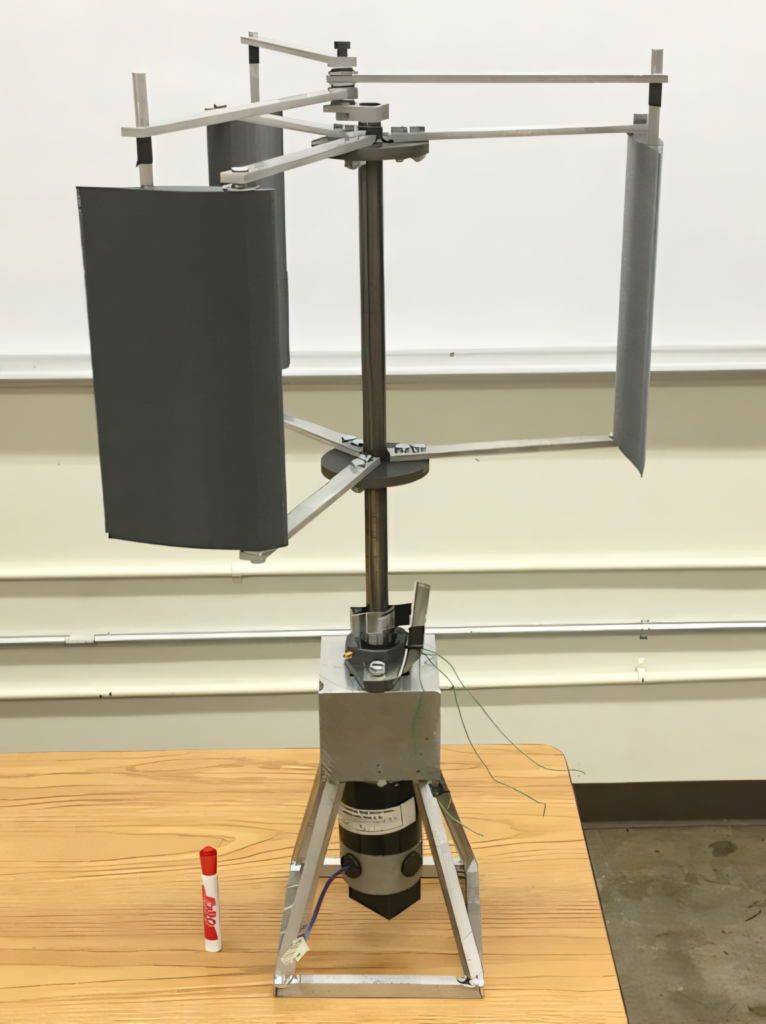

As part of my mechanical engineering courses in college, I designed a vertical axis wind turbine to explore micro-energy generation on a small neighborhood or per-street level. The project involved utilizing a 4-bar linkage system to develop a functional prototype, showcasing the potential for compact and sustainable energy solutions in localized settings.

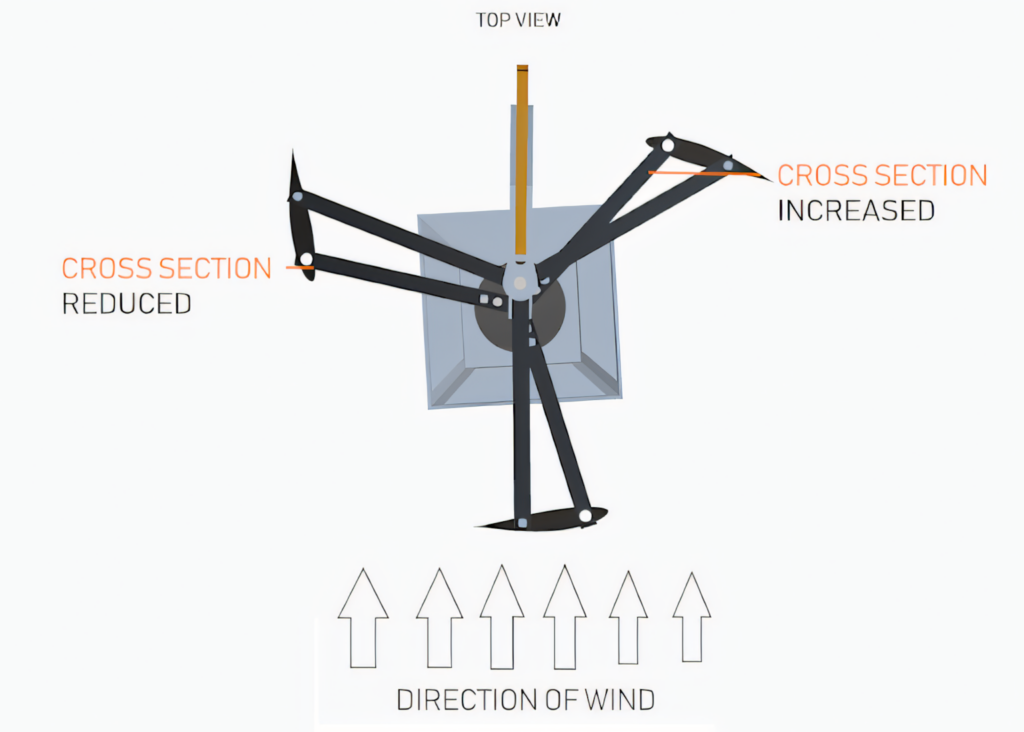

What makes this vertical axis wind turbine different then others? Well it has three multiples of 4-bar linkage systems which all operate in respect to a wind vane. The wind vane points in the direction of the wind while simultaneously shifting the angles of each linkage arm (see right). The yielding force on the system generated by the airfoils increases and decreases when necessary to improve the efficiency of the system.

In the system on the right, counter-clockwise motion is required to yield energy from the system based on the generator (DC motor) internal wiring direction.

Each linkage system is propelled simultaneously by the torque generated from the wind vane (which is dependent on wind direction). The small DC motor (located at the bottom of the assembly) acts as a generator to capture the wind energy.

A series of ball bearings separate the linkage stacks from the main vertical turbine axis.